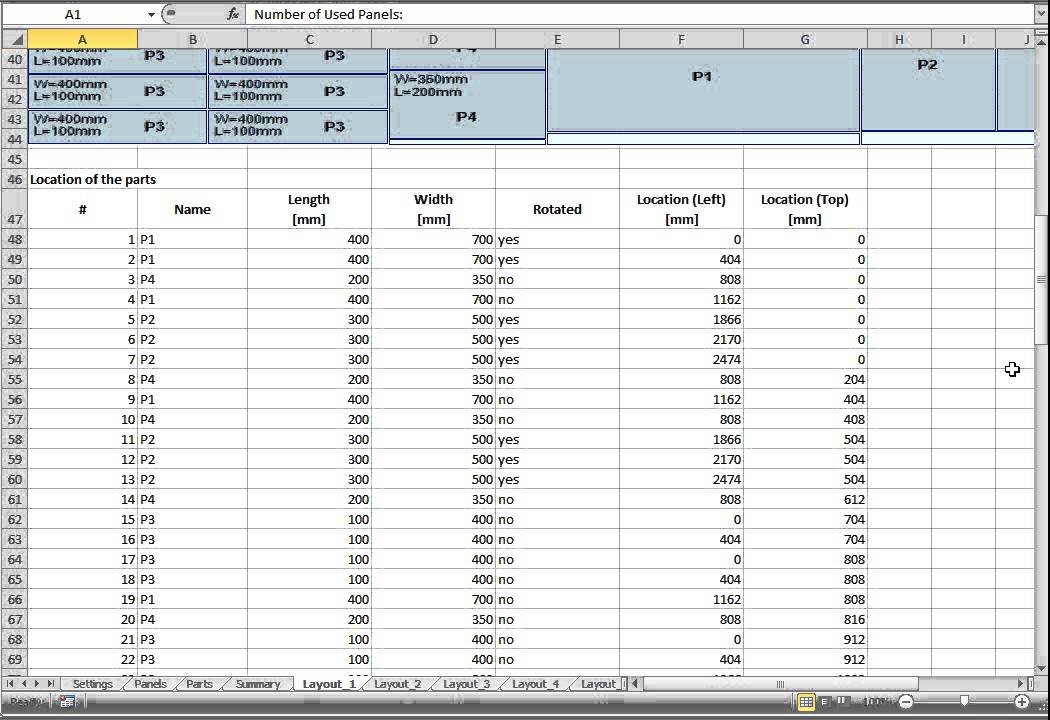

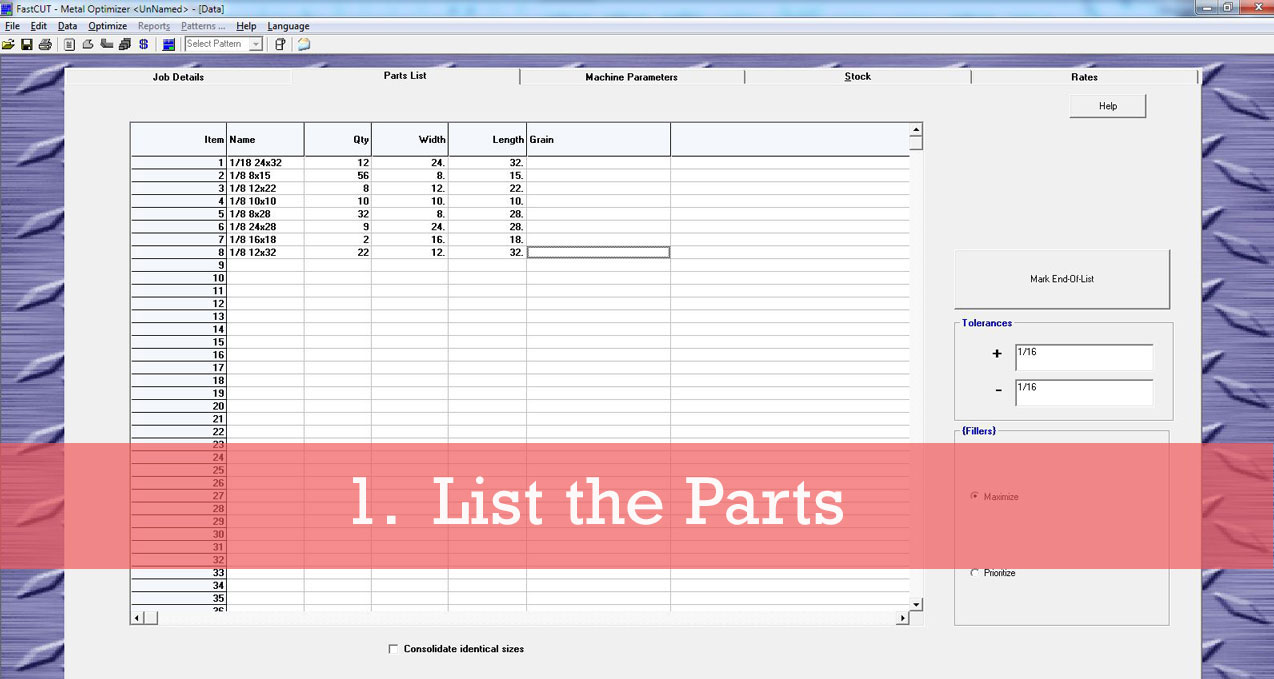

You will have access to the: cuttings definition The cuttings are shown in text format which can be easily adapted for use to a CNC machine.Ĭopy-Paste from Excel - select some data from excel, click on a cell in Demand or Inventory and then press Ctrl+V.Ĭurrent cut / layout- At the end of the optimisation process Graphical and text display of the obtained results. Printing the Stock and the Parts of the customer - you may print the pieces that you want Printing multiple layouts on the same page - this will save a lot of paper. Printing the obtained layouts - on any printer. Reduces panel waste and costs - By using the latest achievements in the field of Artificial IntelligenceĪutomatic offcuts handling - the useful waste is automatically added to the Stock of materials. Your program on any kind of computer (from 486 to the best processorsĭXF export - obtained layouts can be exported to AutoCAD dxf format. You don't have a good computer you may set the Optimization Level to a low level. Level- One may specify how many layouts to be generatedīefore the solution is outputted.

Just choose a metric in your mind and enter all data If all angles have 90 degrees theĪny number of pieces in the Stock and Parts - virtually no limit for the number of pieces that you want to optimize.Īny size less than 2 billion units- the size of the pieces is limited by the size of the data types introduced by the C++ language.Īny measurement metric- The way in which you introduce the data is a general one.

Parts and bars can be entered either as real numbers (such as 100.5) or as fractional values (100 1/2)Ĭompute the cutting order - which is very important if the extremities Having 45 degrees at their extremities you will save as much as theįractional input. A lot of material can be saved by properly matching 2 Pieces to be cut can have angles different of 90 degrees at theirĮxtremities.

0 kommentar(er)

0 kommentar(er)